Table of Contents

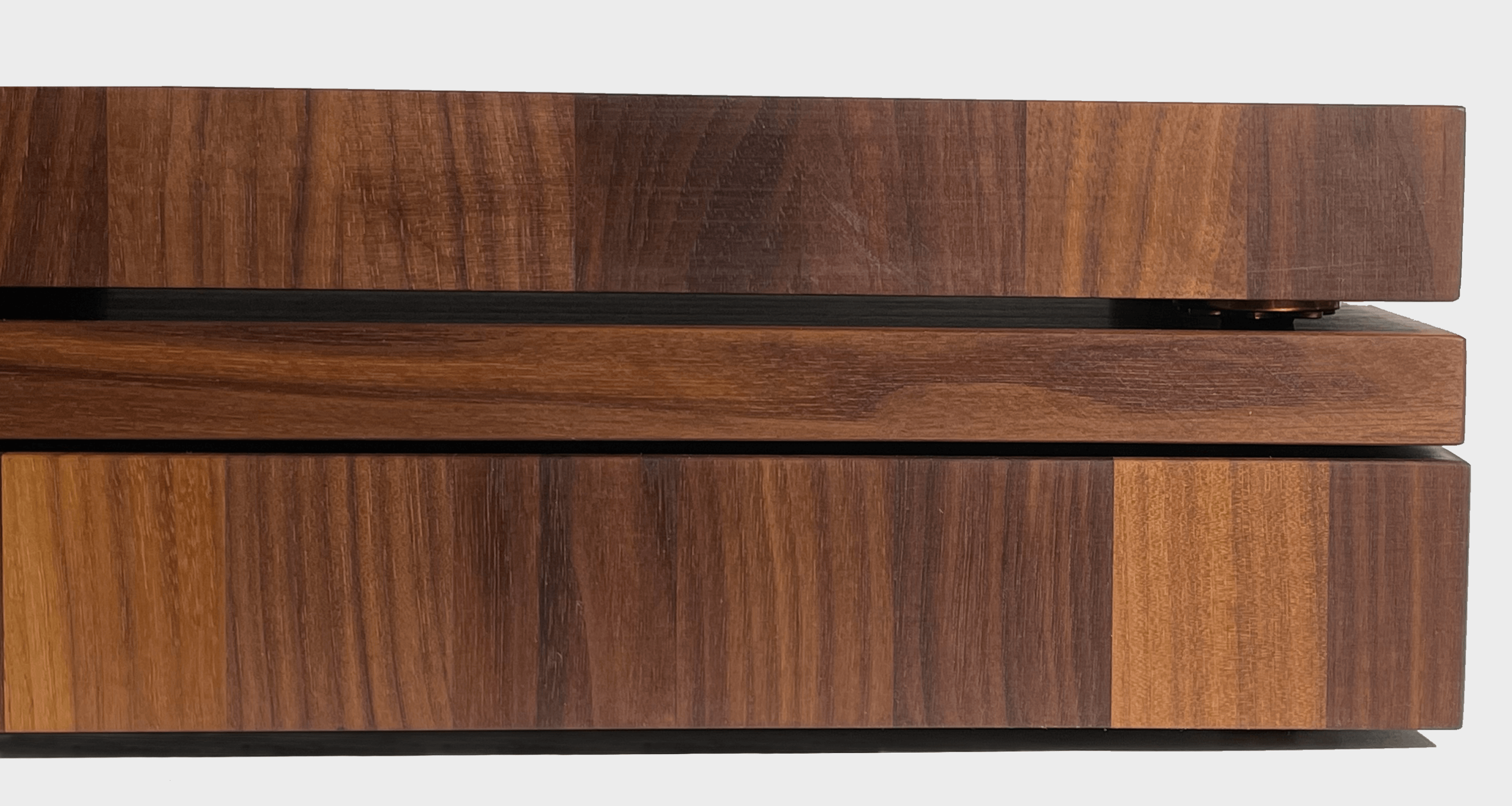

Keep Your Board Flat: Rubber Feet All the Way

Those that advocate for no feet on their wooden chopping boards do so because they prioritise the ability to flip the board and use the other side at the detriment to so many underlying positives of rubber bumpers that defy logical sense.

More Stable

The underneath of a plate has a hollowed out middle. Why is that? Because a totally flat bottom is more likely to wobble. Reducing the amount of contact points is advantageous and offsets any imperfections. The same can be said about a board with rubber feet, by reducing the amount of surface contact points and therefore eliminating wobble. Rubber feet firmly plant your wooden board to the kitchen counter. Those who advocate for a board without feet ultimately end up having to sit the chopping board on top of something soft, either a couple of tea-towels or some sort of silicone matt.

Now ask yourself if you want to deal with the faff? The truth is wood moves no matter what, it's a living thing adapting to it's environment. Even heavy boards that are robust and thick will suffer some movement. Don't get me wrong it will be completely undetectable to the eye, but when slicing and dicing you will notice a little rocking between the chopping board and the kitchen counter top. Which is due entirely to there being too much surface area in contact with the counter top.

If you want to cut on a solid surface without having to do extra steps before starting prep tasks like dig out a few tea-towels then their is only one real option. Cutting boards with feet.

Less Hassle

Those who elect for no feet cutting boards have to go to extra lengths to try to maintain their boards "flatness" in forums you will come across posts who take extra measures in the pursuit of maintaining flatness, standing cutting boards on their side, or storing away when not in use. This can brings up a major issue, you're now restricting the size of your chopping board to the largest storage space you have. We say, leave your cutting board on the kitchen counter top and start cutting on it whenever you like. I know which one of these is more appealing to me.

Also, ask yourself if you want the hassle of sourcing clean tea-towels every-time you want to cut on a stable surface. What will inevitably happen is you won't bother and just instead cut on a rocking chopping board, at which point you may as well be cutting on an inexpensive plastic cutting board because it would be more enjoyable. Alternatively you might decide to have a permanent silicone matt underneath. In which case brace yourself for frequent cleaning as debris is bound to accumulate around the edges, and water will seep in and stagnate in its own filth.

Better Protection

The gap between the countertop and the underside of your wooden chopping board allows for airflow, which is advantageous for wood stability. Also, an elevated wooden board that sits on the counter will not have to contend with water ingress from underneath. Think about the types of cleanup routines that happen during daily kitchen use. Do you find yourself lifting your chopping board to wipe away stray water or food juices during normal kitchen prep activities? You probably do, and if that's the case, having water ingress through the underside of your cutting board because you opted for a chopping board without feet will be a real issue you will need to be aware of and contend with.

We are all in on rubber feet and believe whole heartedly it's the best way to go for longevity. For those adamant that reversibility is the most important thing firstly you'll have to come to terms with the concept of the "Not-Perfectly-Flat Cutting Board". Secondly, opt for the most stable wood species you can, balance that with a wood that has a closed grain structure. A good starting point would be maple boards.

If you're in the market for the very best cutting experience consider an End Grain Cutting Board. For a more affordable option a thick stable board like Edge Grain will be a better fit or maybe you just want some rubber feet for your cutting board?

In that case you can shop the link below to buy the exact bumpers we use.